Products List

Products List Precision molding surrface grinder SGA 618

Precision molding surrface grinder SGA 618 Precision molding surrface grinder SGA 250

Precision molding surrface grinder SGA 250 High precision Surface grinder SGA 2550AH/AHR/...

High precision Surface grinder SGA 2550AH/AHR/...

High precision Surface grinder SGA 3063AHD/NC2

High precision Surface grinder SGA 3063AHD/NC2 High precision Surface grinder SGA 4080AHD/NC2

High precision Surface grinder SGA 4080AHD/NC2 High precision Surface grinder SGA 30100AHD/NC...

High precision Surface grinder SGA 30100AHD/NC...

High precision Surface grinder SGA 40100AHD/NC...

High precision Surface grinder SGA 40100AHD/NC...

Precision molding surrface grinder SGA 416/420...

Precision molding surrface grinder SGA 416/420...

Precision molding surrface grinder SGC 510/512...

Precision molding surrface grinder SGC 510/512...

Precision molding surrface grinder SGC 715/720...

Precision molding surrface grinder SGC 715/720...

Gantry surrface grinder seriess JGS-2210AS

Gantry surrface grinder seriess JGS-2210AS Saddle Type Rotary Grinders KRGH-300/KRGH-400

Saddle Type Rotary Grinders KRGH-300/KRGH-400 Rotary table type

Rotary table type Saddle Type Rotary Grinders

Saddle Type Rotary Grinders Universal grinding machine USM 500

Universal grinding machine USM 500 Cylindrical grinding machine URS 500N

Cylindrical grinding machine URS 500N Cylindrical grinding machine URS 800N

Cylindrical grinding machine URS 800N Cylindrical grinding machine URS 1000N/1500N

Cylindrical grinding machine URS 1000N/1500N Cylindrical grinding machine URS 2000N/3000N

Cylindrical grinding machine URS 2000N/3000N Optical curve grinding machines

Optical curve grinding machines CNC Surface grinder and Profile grinder

CNC Surface grinder and Profile grinder

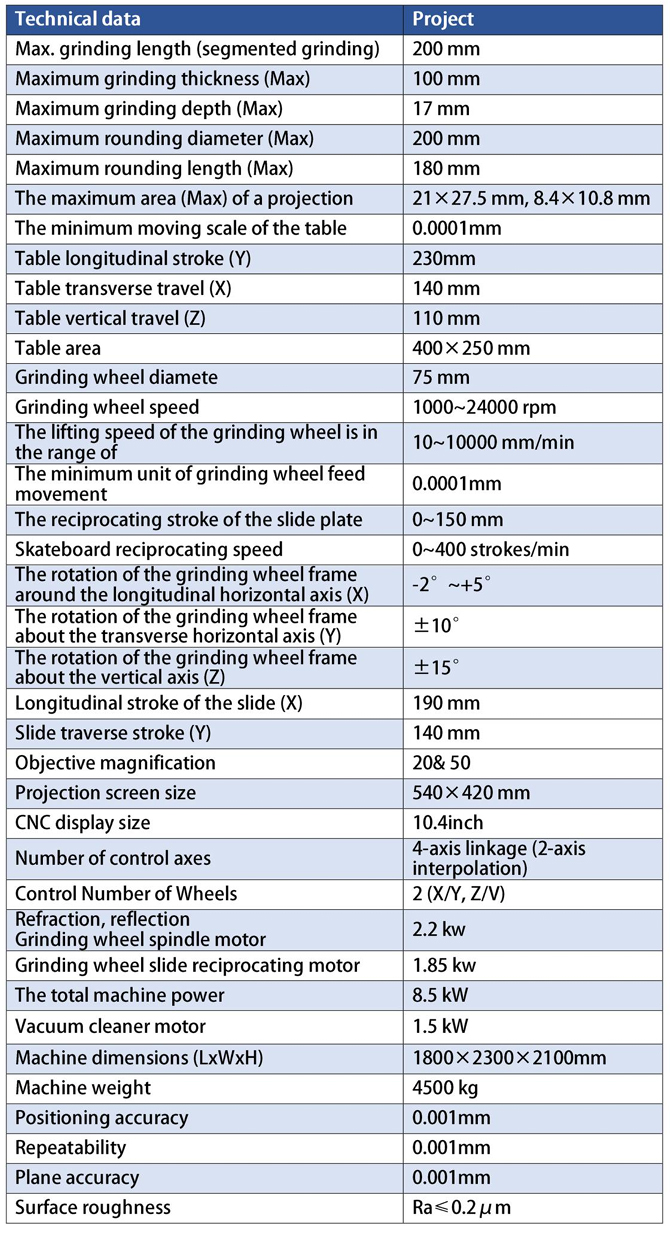

Optical curve grinding machines are used to grind precise and complex profiles, including straight lines, arcs, and curves. Through the refraction of light to reflect the shape of the processing curve, the processing of high-precision parts of the groove, inside and outside r, the shape of complex and high size requirements of the tool, etc., in the grinding process, the workpiece, the grinding wheel can be magnified by the optical system 20 times or 50 times, projected on the screen, when working, the grinding wheel is observed on the screen at any time along the workpiece surface processing, and the workpiece diagram magnified 20 times or 50 times of the film magnification chart is compared, the visual amplifier is used to enlarge the projection magnified graphics again, and the processing situation is observed online. And can manually interrupt or compensate for the processing procedure (if there is a grinding wheel wear, material, feed and other factors can be compensated and changed in time), so as to achieve the sample processing profile and the film times the chart is consistent, after the processing can also be through the projection method to check the workpiece, intuitive and clear. Whether it is during or after processing, the deviation can be observed and corrected in time, and the quality of the processed sample can be known without additional inspection.