Products List

Products List Precision molding surrface grinder SGA 618

Precision molding surrface grinder SGA 618 Precision molding surrface grinder SGA 250

Precision molding surrface grinder SGA 250 High precision Surface grinder SGA 2550AH/AHR/...

High precision Surface grinder SGA 2550AH/AHR/...

High precision Surface grinder SGA 3063AHD/NC2

High precision Surface grinder SGA 3063AHD/NC2 High precision Surface grinder SGA 34080AHD/NC...

High precision Surface grinder SGA 34080AHD/NC...

High precision Surface grinder SGA 30100AHD/NC...

High precision Surface grinder SGA 30100AHD/NC...

High precision Surface grinder SGA 40100AHD/NC...

High precision Surface grinder SGA 40100AHD/NC...

Precision molding surrface grinder SGA 416/420...

Precision molding surrface grinder SGA 416/420...

Precision molding surrface grinder SGC 510/512...

Precision molding surrface grinder SGC 510/512...

Precision molding surrface grinder SGC 715/720...

Precision molding surrface grinder SGC 715/720...

Gantry surrface grinder seriess JGS-2210AS

Gantry surrface grinder seriess JGS-2210AS Saddle Type Rotary Grinders KRGH-300/KRGH-400

Saddle Type Rotary Grinders KRGH-300/KRGH-400 Rotary table type

Rotary table type Saddle Type Rotary Grinders

Saddle Type Rotary Grinders Universal grinding machine USM 500

Universal grinding machine USM 500 Cylindrical grinding machine URS 500N

Cylindrical grinding machine URS 500N Cylindrical grinding machine URS 800N

Cylindrical grinding machine URS 800N Cylindrical grinding machine URS 1000N/1500N

Cylindrical grinding machine URS 1000N/1500N Cylindrical grinding machine URS 2000N/3000N

Cylindrical grinding machine URS 2000N/3000N Optical curve grinding machines

Optical curve grinding machines

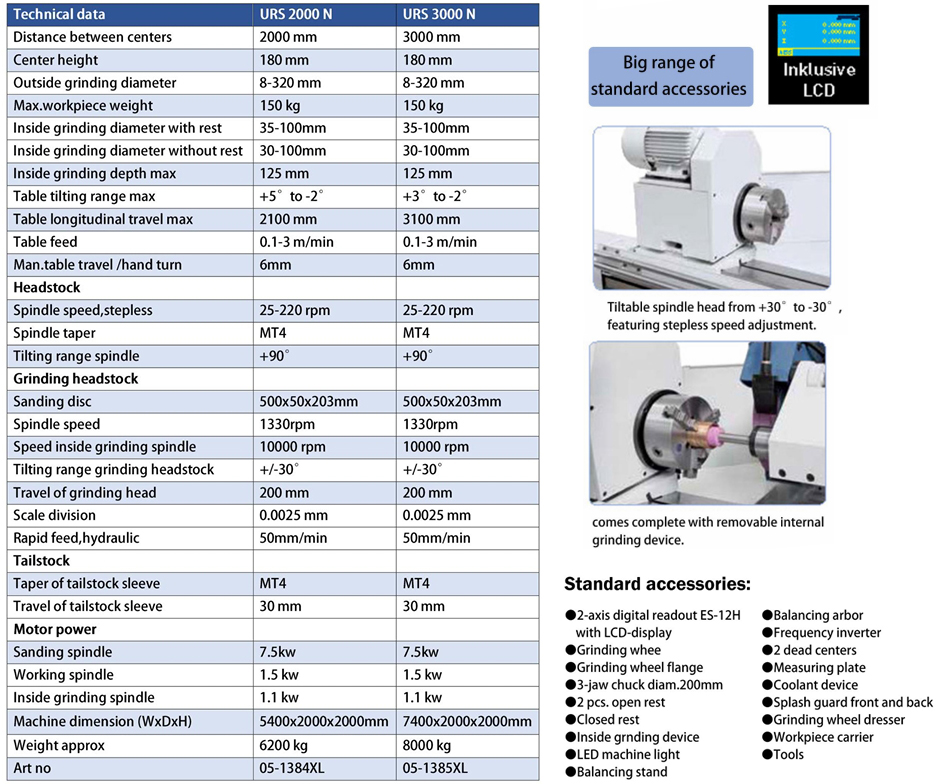

●Oil flm between bearing and spindle keeps vibrations at a minimum level, hence achieving outstanding results and top accuracy

●Precisely balanced spindle head and solid grinding head guarantees extraordinary results at any type of operation

●Strong reinforcements and solidly designed walls of the machine base makes it resistant to temperature fuctuations and deformations

●Spindle is mounted from both sides and features adjustable sliding bearings consisting of three segments Hydrodynamic bearing of spindle, therefore no contact between spindle and bearing

●Longitudinal table feed can be set to automatic mode - hydraulically driven or manual mode - by handwheel

●Stepless feed adjustments with selective programmable hold time at the end of each table movement

●Longitudinal table guide and cross guide of grinding headstock each feature a V-guide and flat guide

●Hydraulic or manual repositioning of grinding spindle stock

●Guideways in x- and y-axis are precisely constructed and hand-polished

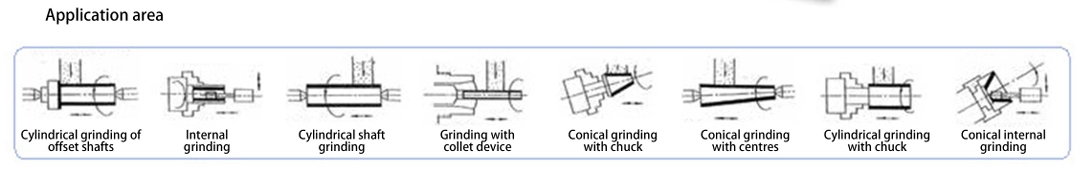

The URS 2000 N and URS 3000 N universal cylindrical grinding machines are suitable for external cylindrical grinding of workpieces up to 320 mm diameter. Part of the standard equipment is the internal grinding device, increasing the range of applications signifcantly. A popular model for machine construction, mould and tool making and production of small series.